Foornada dhalaalka gaaska foornada dhalaalisa ee aluminiumka qashinka dhalada ee foornada leexinta rotary

MAGACA waxsoosaarka:

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

Foornada sifaynta foornada ee rotary

Foornada sifaynta foornada rotary waxaa inta badan loo isticmaalaa sifaynta pyrometallurgical ee biraha dib loo warshadeeyay (badanaa loo isticmaalo naxaasta aan nadiif ahayn). Si loo hagaajiyo tilmaamayaasha farsamada iyo dhaqaalaha ee foornada sifaynta foornada, waxa ugu wanaagsan in la haysto darajada naxaasta oo ka sarreysa 90% marka la gelayo foornada. Alaabta ceeriin ee leh darajooyinka naxaasta hoose, waxa fiican in marka hore daawayn ka hor lagu sameeyo foornada qaraxa iyo foornada afuufista ka hor inta aanad gelin foornada foornada.

Jirka foornada ee foornada wareegta ayaa lagu rakibay qaab wareeg ah, kaas oo, hoos yimaada ficilka dhululubada haydarooliga, wuxuu u leexin karaa jirka foornada gudaha xagal gaar ah si loo gaaro tallaabooyinka habka sida quudinta, dhalaalidda, iyo qashin qubka. Isla mar ahaantaana, jidhka foornada ayaa ku wareegi kara hareeraha dhidibka iyada oo la raacayo ficilka habka gudbinta; Dhaqdhaqaaqa wareega wuxuu hagaajiyaa waxtarka kuleylka foornada wuxuuna muhiimad weyn u leeyahay kulaylka badan ee birta dhalaalaysa.

Markay birta dhalaalayso foornadan, xaddi go'an oo ah wakiilka samayska ah ayaa loo baahan yahay in lagu daro. Walaxda dhalada dhalaalaysa iyo dareeraha dharbaaxadu waxay leeyihiin saamayn difaac ah biraha adag iyo kuwa dareeraha ah, taas oo ka hortagi karta oksaydhka birta

Heerka luminta gubida walxaha sida silikoon iyo manganese ee ku jira koob rotary ayaa u dhigma kan kookaha gubanaya cupola. Waxyaabaha ku jira walxaha kaarboonka ee foornada wareega ayaa sii yaraanaya, sidaas darteed waxaa lagama maarmaan ah in lagu daro qadar gaar ah oo ah wakiilka carburizing (coke ama graphite) ee alaabta foornada.

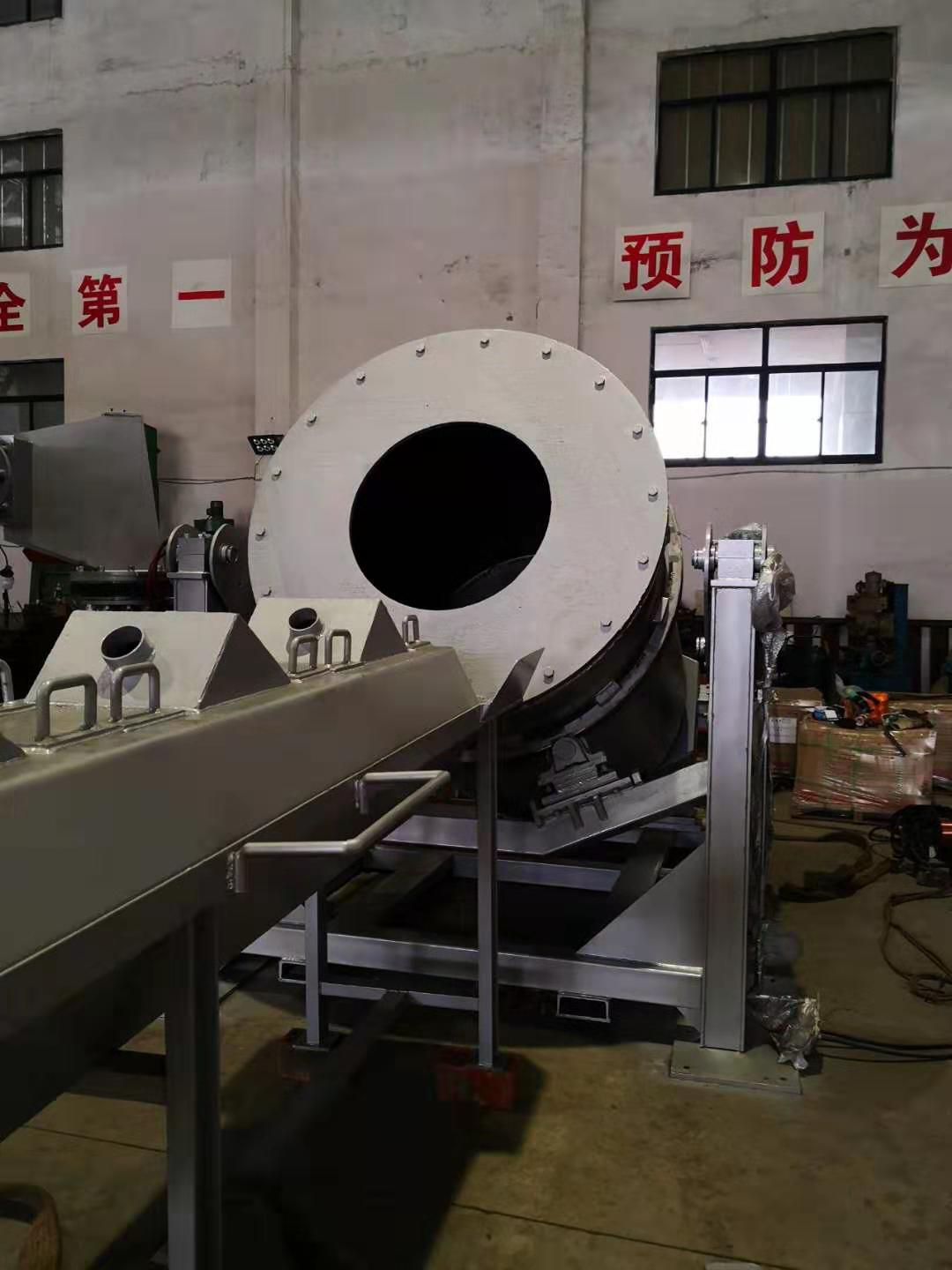

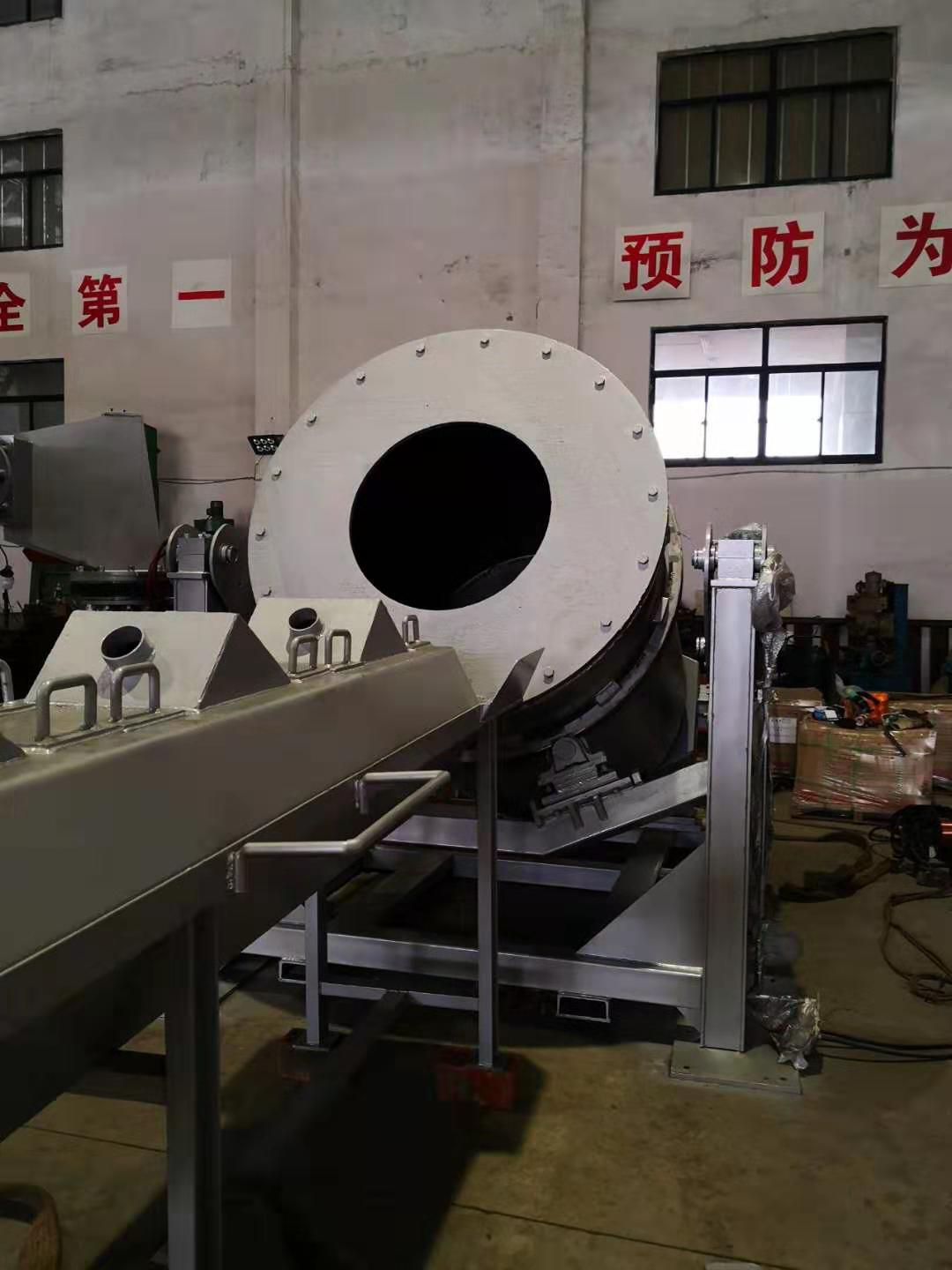

SAWIRRADA SOO SAARE:

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

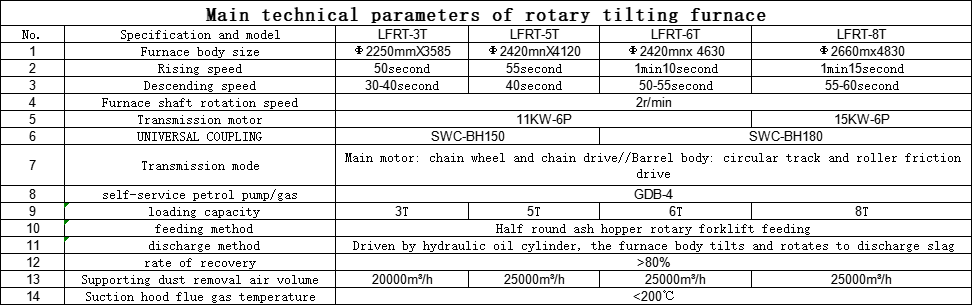

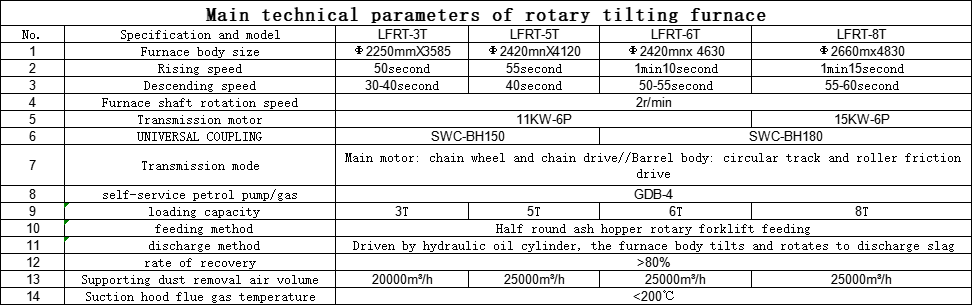

QAABKA:

QAABKA:

foornada gaaska foornada dhalaalaysa ee aluminiumka qashinka ah ee dhalaalinta rotariga ah foornada

English

English  Español

Español  Português

Português  русский

русский  français

français  日本語

日本語  Deutsch

Deutsch  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ไทย

ไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  Malay

Malay  বাংলা

বাংলা  हिन्दी

हिन्दी  Pilipino

Pilipino  Türk

Türk  عربى

عربى  Indonesia

Indonesia  norsk

norsk  čeština

čeština  Українська

Українська  Javanese

Javanese  فارسی

فارسی  తెలుగు

తెలుగు  Burmese

Burmese  български

български  Latine

Latine  Azərbaycan

Azərbaycan  Српски

Српски  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  Cymraeg

Cymraeg  Беларус

Беларус  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Bosanski

Bosanski  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  IsiXhosa

IsiXhosa  Chichewa

Chichewa  Somali

Somali  O'zbek

O'zbek  հայերեն

հայերեն  Sundanese

Sundanese  Malagasy

Malagasy